Services

OEM / ODM Design & Manufacturing Services

Processing procedure

NEW TIDE provides OEM / ODM design and manufacturing services, covering product design, development, production, and quality management. With advanced technology and a professional team, we deliver customized, high-quality products that enhance efficiency and market competitiveness. All of the processes comply with ISO 9001, ISO 14001, RoHS, and REACH standards, serving industries such as electronics, machinery, and consumer goods. We help clients accelerate time-to-market, reduce costs, and ensure stable product quality to create a stronger competitive advantages.

SERVICE.01

Electroplating

Electroplating is a surface treatment process that uses electrolysis to deposit a thin metal coating onto a conductive material. It enhances appearance, corrosion resistance, wear resistance, and conductivity. Common plating metals include nickel, chromium, gold, and silver, widely applied in automotive, electronics, and industrial equipment.

01

SERVICE.02

Anodizing

Anodizing is an electrochemical process that forms a protective oxide layer on aluminum and its alloys, enhancing corrosion resistance, hardness, wear resistance, and dye absorption. It is widely used in aerospace, automotive, and electronics industries to improve durability and aesthetics.

02

SERVICE.03

Baking Paint

Baking paint is a coating process where paint is sprayed onto a surface and then heat-cured to form a smooth, durable, and corrosion-resistant finish. It is widely used in automotive, home appliances, and architectural applications, offering excellent adhesion, wear resistance, and color variety.

03

SERVICE.04

Electrophoretic Coating

E-coating is an electrochemical deposition process that applies a uniform protective and decorative coating to metal surfaces. It enhances corrosion resistance, durability, and aesthetic appeal, commonly used in aluminum alloys, automotive parts, and electronic components. It would possible realize various color options and have features of environmental protection, durability and strong adhesion.

04

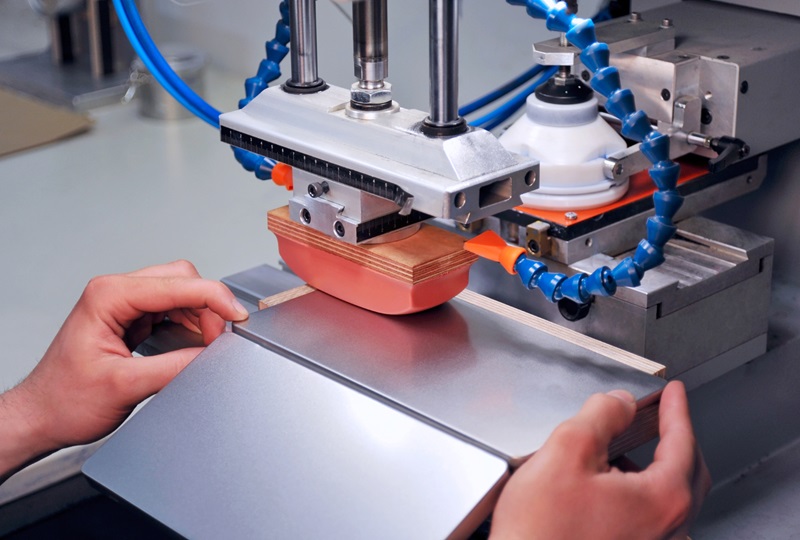

SERVICE.05

Screen Printing

Screen printing is a technology which can transfer design onto flat or slightly curved surfaces using a mesh stencil. It allows clear and durable printing of model numbers, logos, and markings, making it ideal for customized labeling on connectors and electronic components.

05

SERVICE.06

Pad Printing

Pad printing is a printing method which can use a silicone pad to transfer designs from an etched plate onto the surface of an object. It is especially suitable for irregular shapes or curved surfaces. This technology is allowed to precise and detailed printing of logos, model numbers, and various markings. It is widely used in the electronics industry, particularly for connectors and other components with complex structures or fine dimensions.

06

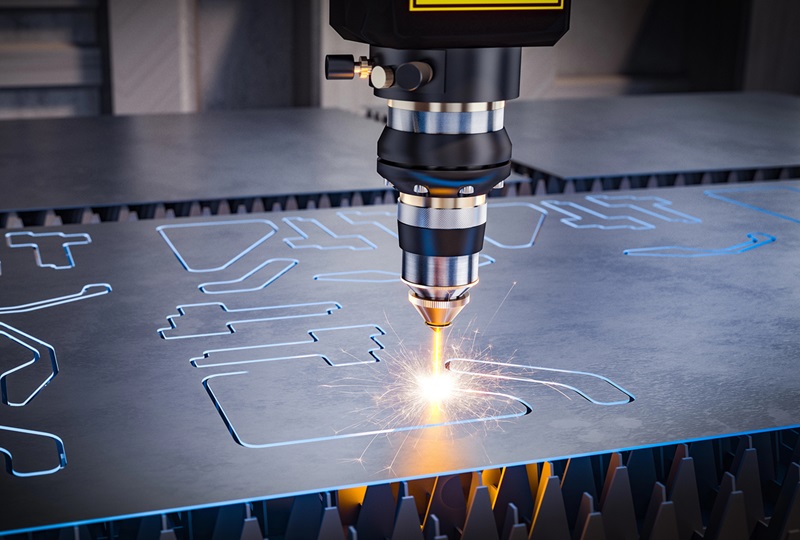

SERVICE.07

Dispensing & Sealing

Dispensing and sealing involve the precise application of adhesives, resins, or sealants to bond components, insulate electrical parts, and provide waterproofing or dust protection. These processes are essential in electronics, automotive manufacturing, packaging, and medical devices.

07

SERVICE.08

Laser Engraving

Laser engraving is a high-precision marking technique that uses a focused laser beam to create permanent engravings on metal, plastic, glass, and wood. It offers high accuracy, wear resistance, and non-fading markings, widely used in electronics, industrial parts, and personalized engraving area.

08